Turning + Mill-Turn Solutions

PRODUCT OVERVIEW

SolidCAM Turning

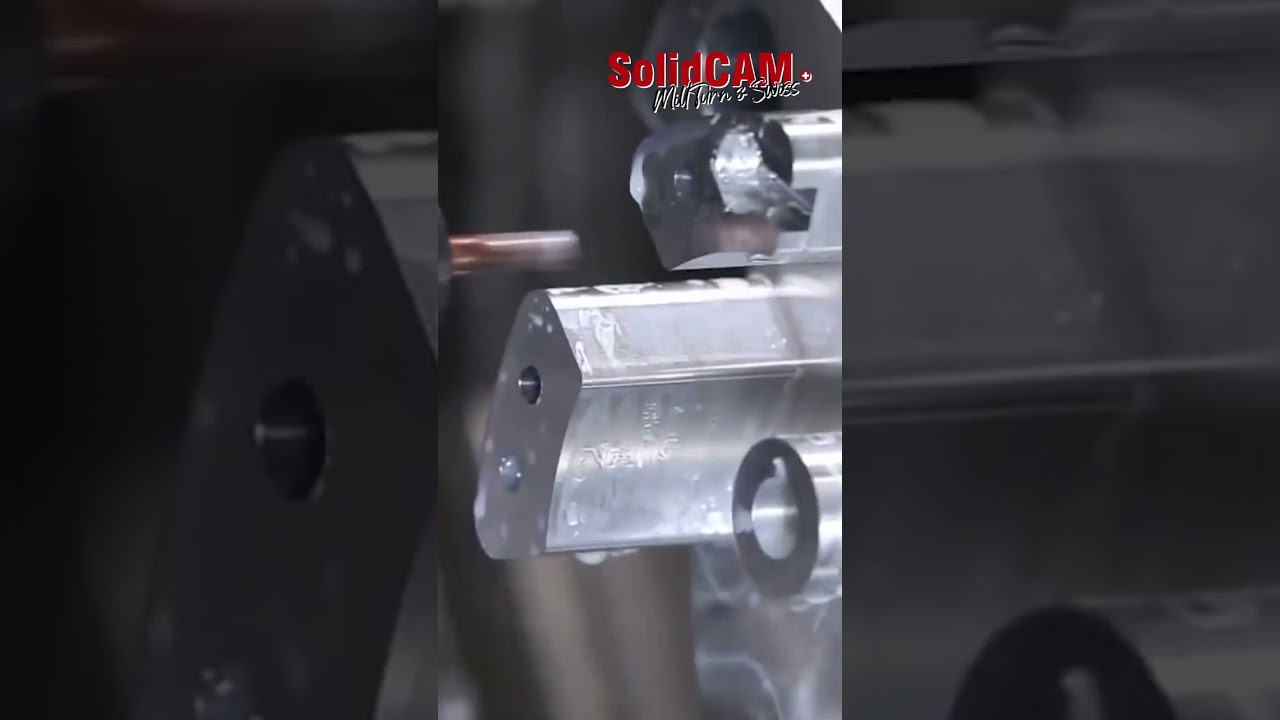

SolidCAM’s Turning and Mill-Turn solutions provide an integrated environment for both turning and milling operations—including 2.5D, 3-axis, and full 5-axis milling—within the same CAM platform. From simple profile turning to complex mill-turn synchronization, SolidCAM allows you to program, simulate, and optimize all operations in one workflow.

With complete machine awareness, stock tracking, and collision detection, you gain the confidence to run advanced turning and milling processes on everything from 2-axis lathes to sophisticated multi-turret, multi-spindle mill-turn machines. The result: a more efficient workflow, reduced errors, and faster time to finished part.

Why Choose SolidCAM

Faster Time to Part

By combining turning and milling in one environment, you eliminate the need to move between multiple CAM systems. This reduces programming time and streamlines setups.

Reduced Risk of Costly Errors

Accurate stock tracking and full machine simulation with collision detection let you validate processes before cutting, helping avoid scrap and machine damage.

Flexibility Across Machine Types

Whether you’re programming a simple lathe or a complex 5-axis mill-turn center, the same solution adapts to your machine configuration.

Mill-Turn Videos

Turning + Mill-Turn

0:15

0:09

0:13

0:05

0:18

Key Features

Here are the advanced features you get with our Turning packages:

Integrated Milling (2.5D, 3-Axis, 5-Axis)

Adds full milling power—including 2.5D pocketing, 3-axis surface machining, and simultaneous 5-axis contouring—directly into turning workflows.

Multi-channel Synchronization

Programs multi-channel operations with control over spindles, turrets, and axes, ensuring coordinated machining on advanced equipment.

Machine Simulation & Collision Detection

Provides realistic visualization of machine kinematics, including part transfers, with automatic collision and clash checking.

Dynamic Stock Tracking

Maintains live stock status across all operations and transfers, ensuring accurate toolpath generation throughout the process.

Custom & Advanced Tooling Support

Accepts complex tool definitions such as multi-cutter holders, HDT, and FreeTurn tools, expanding machining strategies.

Tailstock, Steady Rest & Part Transfer Management

Supports auxiliary components and operations for accurate, stable machining of long or complex parts.